Metal Lattice Panels - METART-WW30L - The ideal choice for railing infills

Type of Mesh: Super Rigid Architectural Wire Mesh

Optional Materials: SS201, SS304, SS316, SS316L

Finish: Mill Finish ( other optional finishes, plz refer to the following spec table)

Weight: Approx 8.29kg/Square Meter

Screen Width: up to 1.4M for color alloy plated finishes. (4.59 feet)

Screen Length: up to 4M for copper alloy plated finishes. (13.12 feet)

GET A QUOTE

Metal Lattice Panels

In our product category, metal lattice panels typically refer to decorative metal lattice sheets or architectural metal mesh panels that enhance the overall decorative atmosphere while maintaining essential functionality.

The Origination of Architectural Pattern Code METART-WW30L

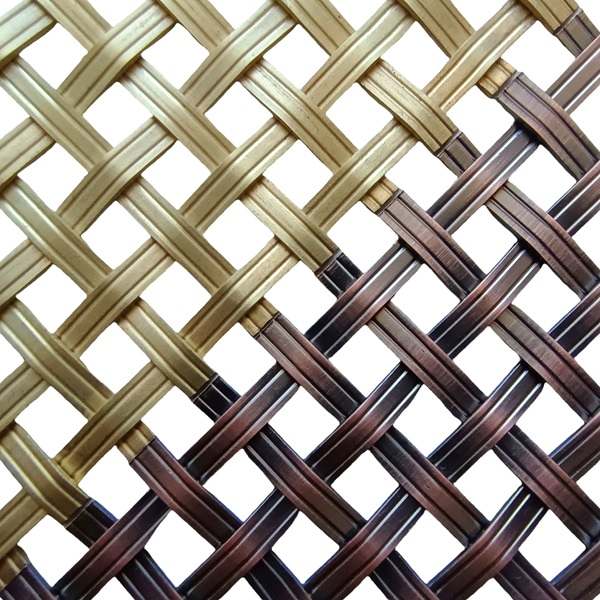

As the name suggests, We can easily tell that METART-WW30L is a variant of the classic privacy metal lattice panel "METART-WW30".

The additional "L" indicates that this is an enhanced version, featuring larger diameter metal wires and larger opening sizes.

The differences between these two patterns are characterized by three key factors.

• The wire diameters for "METART-WW30" are 1.65 mm and 1.8 mm, while the METART-WW30L utilizes stronger wires measuring 2.35 mm and 2.45 mm, resulting in an approximate 40% increase in strength compared to the original design.

• The slot opening of "METART-WW30" is 2 mm x 11 mm, whereas the opening size for METART-WW30L is larger, at 2.3 mm x 16.8 mm.

• The rigidity of METART-WW30L is significantly enhanced.

Manufacturing of METART-WW30L Metal Lattice Panels

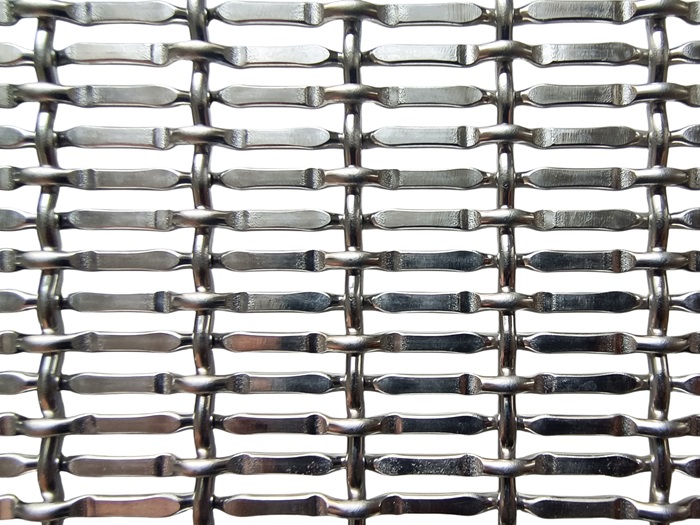

This lattice metal screen is made of 2.35mm vertically, considered warp wire in the metal wire weaving industry, and the other direction 2.45mm before being cold-rolled. After it is shaped, the flattened part is measured around 2.8mm wide and 1.5 to 1.6mm thick. The warp wires are spaced approximately 19.1mm apart, while the weft wires are about 5.1mm apart.

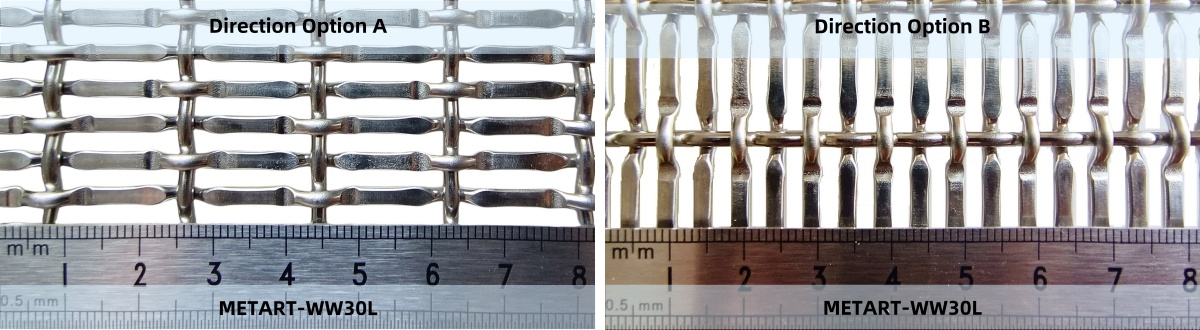

As this is a slot hole stainless steel lattice, customers need to pay attention to the direction when palcing an order. It is not important at the estimating stage. But It is crucial to figure out how you will use it before ordering. Please refer to the following picture for comparison and quote the correct option while making a purchase.

Two key factors in producing this architectural stainless steel lattice include:

► Custom Made High-Tensile Wires

These panels are made from well-chosen, high-tensile stainless steel wires with a tensile strength between 1000 and 1100 MPa. This means that a lot of force is needed to break a single wire.

In comparison, plain weave wire mesh usually uses wires with a tensile strength of 600 to 700 MPa, so this decorative lattice is about 60% stronger, providing better strength and safety for your building projects.

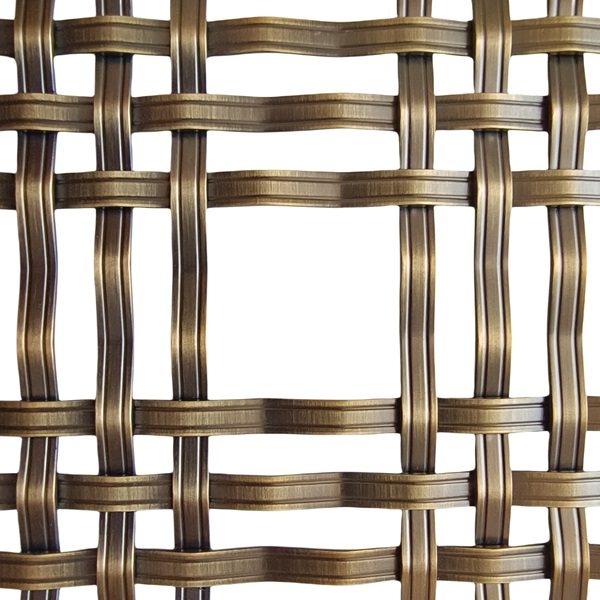

► Carefully Rolled Decorative Wires

The stainless steel wires are carefully machined using special hard alloy tools and are cold-rolled under high pressure to create the right decorative finishes and shapes.

After the wires are cut to size, they are threaded into the loom’s heddles and set in the weaving reed.

Because of the heavy-duty nature of the lattice, the weaving process takes longer time than regular lattice metal.

Product Specification Data Sheet

|

Pattern Code |

METART-WW30L |

|

Optional Materials |

SS201, SS304, SS316, SS316L and other alloys |

|

Type of Lattice |

Supper Rigid Metal Lattice |

|

Decorative Wire Strips Size (Flattened wires) |

2.45mm before being cold rolled, approx. 2.8x1.5mm after |

|

Diameter of Regular Crimped Wires |

Approx 2.35MM |

|

Slot Opening Size |

2.3mm x 16.8mm |

|

Decorative Wire Strip Centers (Flattened wires) |

5.1mm |

|

Regular Crimped Wire Centers |

19.1mm |

|

Overall thickness |

5.5mm |

|

Opening Area |

39.6% |

|

Privacy Rate |

60.4% |

|

Weight |

Approx 8.29KG/Square Meter |

|

Optional ways of cutting |

Straight Cut only |

|

Optional Finishes |

Mill Finish ( Original stainless steel finish) Antique Copper / Bronze / Brass Plated Finishes Titanium-based PVD plated. PVDF Painted Finish |

Expanding Material Horizons - Beyond Stainless Steel

The most suitable and widely used raw material for this architectural pattern is always stainless steel. However, this does not mean we cannot produce it in other materials.

Stainless steel is often chosen because of its excellent physical and chemical properties. It is durable and corrosion-resistant, can be coated or plated with various decorative finishes, and has excellent weldability, making it ideal for all sorts of architectural applications.

Besides stainless steel, there are many other materials, especially precious metals like 100% pure copper, brass, and phosphor bronze, which are renowned for their rarity, inherent beauty, and decorative appeal.

Copper

A chemical element with the symbol Cu (from the Latin word Cuprum) and atomic number 29.

It is a soft, malleable, and ductile metal with exceptional thermal and electrical conductivity.

It possesses a unique pinkish-orange luster that no other coatings can replicate or match.

When exposed to air, copper undergoes oxidation, gradually turning from its fresh reddish hue to a darker shade of brown.

Most importantly, heat will accelerate this process, with new copper wires appearing bright reddish initially, then darkening over time.

Producing this decorative design in copper is simple for us, but preventing it from oxidation remains a big challenge.

Some professional buyers have methods to slow the aging process, but these solutions are often costly.

Brass

A widely used copper alloy composed of approximately 60% copper and roughly 40% zinc, is another popular choice for interior architectural decoration.

Like pure copper, brass also quickly oxidizes when exposed to air, developing a patina that evolves into a rich antique finish over time.

it is unwanted most of the time, but also a good choice for customers who are aiming to create a vintage or worn-in aesthetic.

Phosphor Bronze

A higher copper alloy containing up to 90% copper, with tin (0.5–11%) and phosphorus (0.01–0.35%) as the primary additional elements.

Its fresh metallic golden-brown color, often with a reddish tint, is visually striking. However, like copper and other copper alloys, it is also prone to oxidation and its color may also change during production, shipping, and storage.

Copper and its alloys are highly malleable, making them less tensile compared to stainless steel when using wires of the same diameter. If you are considering decorative lattices made from pure copper or copper alloys, please note that these materials naturally age and change color over time. Additionally, it's important to take into account their relatively lower strength when evaluating their suitability for your specific application.

Aluminum

For lighter-weight options, 5-series aluminum alloy is an excellent choice for producing this pattern. Aluminum products are ideal for powder coating or painting, offering both durability and customization. Please note that the default aluminum grade used in our factory is 5154.

Steel

While steel is not commonly preferred for architectural projects due to its susceptibility to rust and lower aesthetic appeal, it can be a cost-effective option for customers who prioritize design over durability.

Wide Scope of Applications

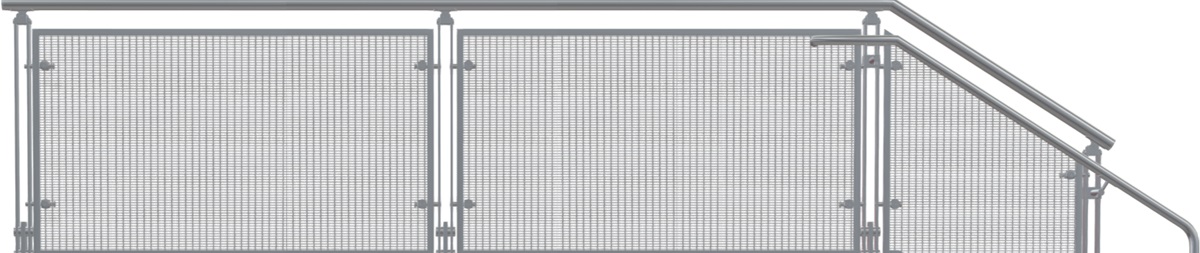

► Railing Infills

This robust and heavy-duty design is an excellent choice for railing infill panels, particularly in commercial buildings such as shopping centers, museums, hotels, supermarkets, schools, and retail shops.

It strikes a perfect balance between providing enhanced security, often a top priority in these spaces, and serving as a captivating architectural element. For residential applications, this mesh pattern is equally suited for balustrades in villas or other upscale properties, seamlessly integrating with any bespoke framing system to deliver both safety and aesthetic appeal.

► Partition Infill Screen Panels

These panels are often elegantly framed and finished with premium coatings, such as PVD plating or antique finishes in copper, brass, or bronze, adding an elegant and timeless vibe to interior partitions.

► Decorative Wire Mesh Wall Panels

Wire mesh panels can be used to create stunning wall features to elevate the interior decoration design, offering an opportunity to combine architectural flair with protective functions, making them a versatile choice for interior spaces.

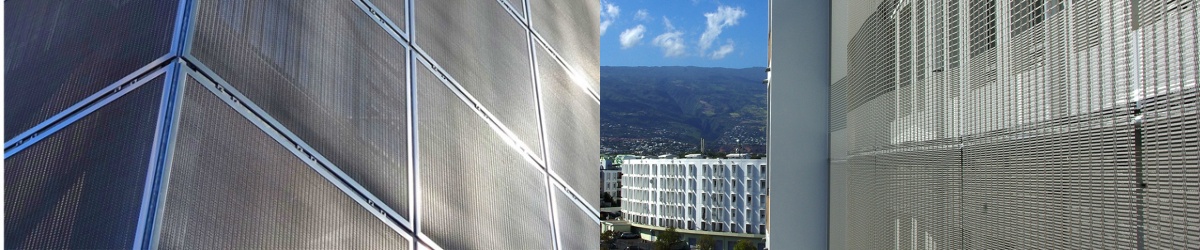

► Building Facade Panels

Always made of marine-grade 316 or 316L stainless steel, these panels are an excellent cladding material for building enclosures.

Always made of marine-grade 316 or 316L stainless steel, these panels are an excellent cladding material for building enclosures.

These wire mesh screens can be supplied with or without frames, depending on design requirements. With a relatively moderate open area of approximately 40%, these panels offer several practical benefits, including:

Solar Control:

They help regulate sunlight exposure, reducing heat gain and enhancing energy efficiency.

Privacy and Shading:

The mesh provides privacy for the interiors while maintaining a shaded environment.

Ventilation:

The design ensures sufficient airflow, allowing fresh air to circulate throughout the building continuously which is eco-friendly.

Infill Panels - Architectural Wire Mesh

Metal Mesh Railing Infill Panels - Made of Stainless Steel Decorative Wire Strips

Architectural Wire Mesh Railing Infill Panel - Made of Decorative Metal Ribbons - METART-WW44-51226

Architectural Metal Mesh made of architectural metal strips.

Architectural Wire Mesh Railing Infill Panel - Made of stainless steel decorative wires

Designer Metal Strips Woven

Designer Metal Antique Bronze Finish - Perfect Infill Panel for Partitions and Space Dividers

Antique Copper Plated Decorative Mesh Wire Dia.1.8mm before flattened, 3.2mm wide after

METART-WW30 Antique Copper Decorative Screen Mesh made of Architectural Wire

©COPYRIGHT METART BUILDING TEC CO., LTD | ALL RIGHTS RESERVED | PRIVACY POLICY