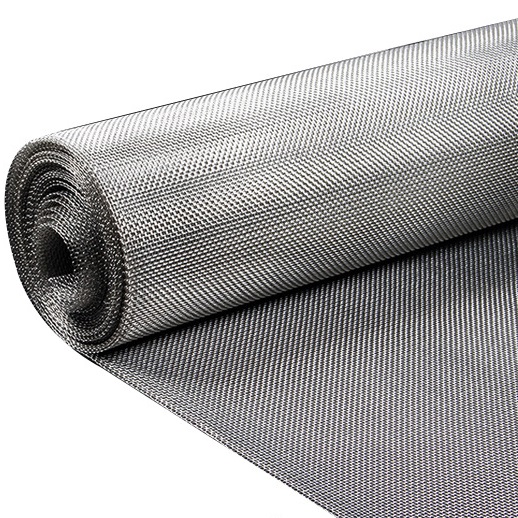

• Aluminum – Low weight alongside aesthetic and structural applications.

• Mild Steel – Economical and common in most industrial applications.

• Stainless Steel – Great for Aluminum due to corrosion.

• Galvanized Steel – Frame or base material to protect against rust.

Key Features

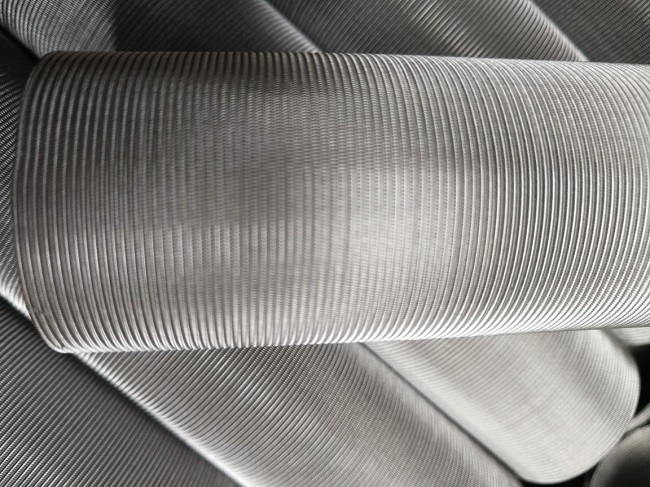

✔ High durability and resistance to wear and tear.

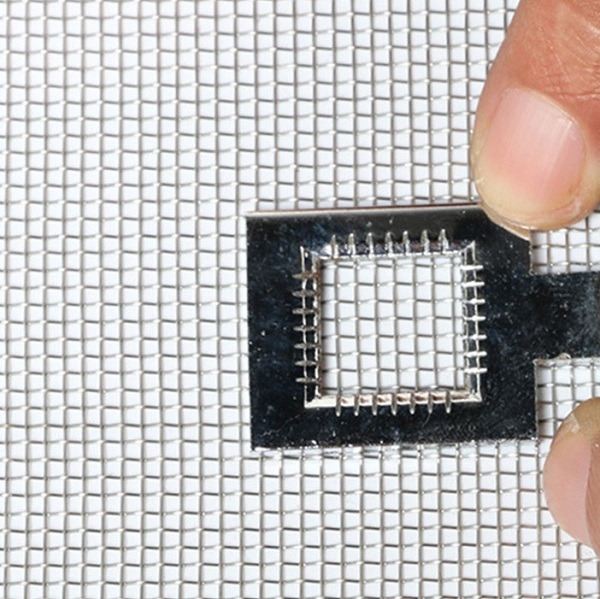

✔ Adjustable perforated shapes for targeted uses.

✔ Improved air circulation and filtration.

✔ Superior strength and light weight.

✔ Pickled, polished, and mill finishes are all offered.

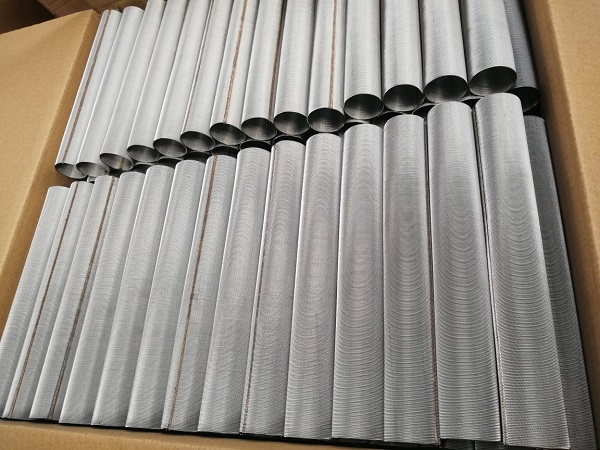

Uses of the Perforated Metal Cylinders

Because of their multifunctional nature, they are handy in a variety of fields. Their use is not limited to being functional filters but also serve structural and artistic purposes.

1. Filtration and Separation Applications

These perforated cylinders are extensively used for filtration systems. They are common in the following industries:

• Oil and Gas - It is used for the purification of crude oil and Natural gas.

• Water Treatment – Removing sediments and other particles for safe drinking water.

• Pharmaceuticals - Used to maintain clean environment for drug preparations.

• Food Processing – Used for Filtration food processes for Quality and safety of products.

Because of its perforated design, these metal cylinders are more effective in capturing harmful particles without obstructing the flow of liquids, thus making them ideal for high performance filtration systems.

2. Architectural and Decorative Applications

Perforated metal cylinders are as common in architecture and interiors as they are in peripheral filtration systems. They are specially known for:

• Beauty – Building facades, decorative columns, and panels.

• Acoustics – Can be tuned to increase sound absorption for speakers.

• Support – Can be provided in a column or panel with openings for a lightweight structure.

3. Automotive and Aerospace Sector Overseas

Perforated metal cylinders help to enhance productivity in the automotive industry and aerospace engineering by:

• Exhaust Systems – Increasing the control emission systems effectiveness.

• Air And Fluid Filtration – Engine filter system for protection against other particles contamination.

• Weight Reduction – Adding strength without the excess mass.

Benefits of Perforated Metal Cylinders

While some argue that competitively priced perforated metal cylinders target primary functions only, in reality, they deliver much more. Here are some of them:

✔ Durability – It can withstand extreme amounts of pressure, temperature change, and corrosion.

✔ Lightweight – Perfect for situations in which minimization of weight is extremely important.

✔ Customizability – Different hole, pattern, and material configurations are available for selection.

✔ Aesthetic Flexibility – Allows for increased creativity in ornamental applications.

✔ Environmentally Friendly – Can be recycled completely.

Metart Building Tech: The Best From All Metal Cylinder Manufacturers

With their experience, Metart Building Tech is able to produce high quality perforated metal cylinders within any specific requirements of industries across the globe. They are leaders in the field of manufacturing owing to their super tight precision, massive strength and balanced functional capabilities.

Who Else But Metart Building Tech

Customer Centricity – Metal cylinders with perforation can be made to order at client’s specification with regard to the material, the size of the perforation, the type of finish, etc.

Broad Industry Coverage – Supplies perforated metals like stainless steel, mild steel and expanded metal sheets.

THIRD LEVEL HEADER METAL FINISHING Other Services Providing Quality Management And Control Exceeds International Standards Completeness Of Work Is Provided Fully Closing Step

Optimal Performance In Every Industy – New ways in which futuristic technologies manufacturing allows Metart Building Tech to penetrate soft goods enabling ease of use and application across various sectors.

Fast Turnaround Delivery And Supply Industries – Providing fast shipping times along with industrial supply for put thousands of industries around the world.

Final Remarks

This makes perforated metal components a highly valuable product for filtration, architecture, automotive, and aeronautical engineering. Their strength and ability to be tailored to suit any industry's requirement make them highly sought after.

With Metart Building Tech, any market will always be sure to find its needs satisfied with the best quality perforated metal cylinders that maintained high structural strength and provided custom functionality. That being custom features might be required for industrial filtration, architecture, and automotive designs, the company always has a specialized team at hand that is always ready to provide them.

Metart Building Tech is the go to company for businesses that seek quality, creativity, and unmatched experience when it comes to manufacturing components from perforated metal.

+86 158 0318 7372 / +61 435 598 786

+86 158 0318 7372 / +61 435 598 786

+86 158 0318 7372 / +61 435 598 786

+86 158 0318 7372 / +61 435 598 786