Decorative Metal Mesh for Lift Car Cladding - METART-WW33-2H

Pattern Code: METART-WW33-2H

Material: SS304+Brass or SS316+Brass

Type: Opaque Decorative Metal Mesh for Caldding

Weight: Approx 13.2kg/Square Meter

Sheet Size: up to 2x4M = 6.56' x 13.12' (For mill finish only)

GET A QUOTE

Enhance Lift Interiors with Decorative Metal Mesh

Decorative metal mesh refers to mesh-structured metal manufactured through different technologies, primarily including weaving and perforation. Occasionally, welding is also used to produce this mesh, but all items must be visually striking, attractive, and good-looking to elevate a space, especially in commercial settings. Thanks to the diverse choices of decorative metals, many metal alloys can be used to make this product, primarily including stainless steel, brass, copper, bronze, and aluminum. Decorative metal mesh is a transformative material for contemporary design, widely used in interior architecture and decoration, with applications including cladding, partitioning, railing systems, and many more.

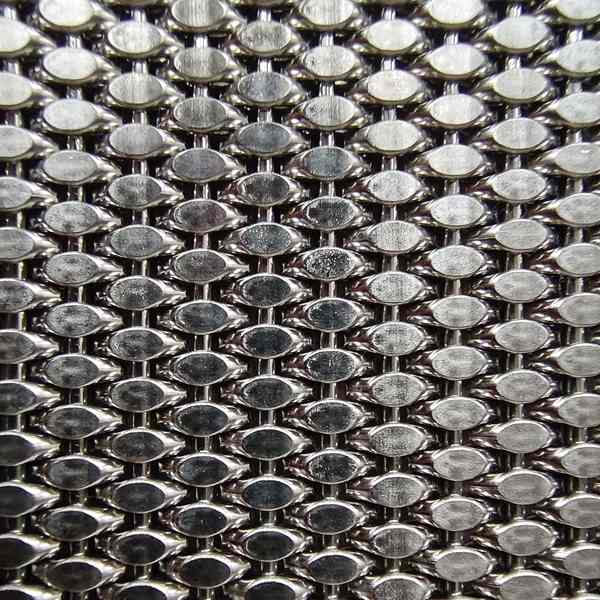

Introduction to "METART-WW33-2H" Decorative Metal Mesh Design

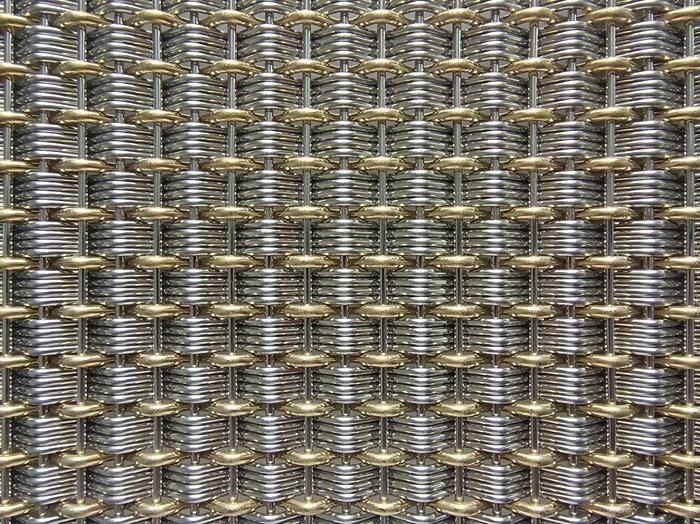

The "METART-WW33-2H" is a solid yet decorative designer metal mesh panel crafted through a hybrid weaving process of stainless steel wire clusters and architectural brass wires. This hybrid material weaving technique — widely used in architectural wire mesh design and manufacturing — integrates the original warm hue of premium brass into conventional stainless steel wire weaves.

The authentic brass wires provide a true metallic golden touch, adding approximately 10% - 15% warm tones to the overall decorative metal panels. This enhancement significantly elevates the design of metal wall screens.

The decorative wire mesh design is ideal for commercial cladding projects, including:

• Hotel lift car cladding

• Luxury store display wall cladding

• High-end villa elevator and lobby cladding

► Specification Overview

|

Optional Materials |

SS304+Brass, SS316+Brass |

|

Type of Mesh |

Rigid Decorative Metal Mesh |

|

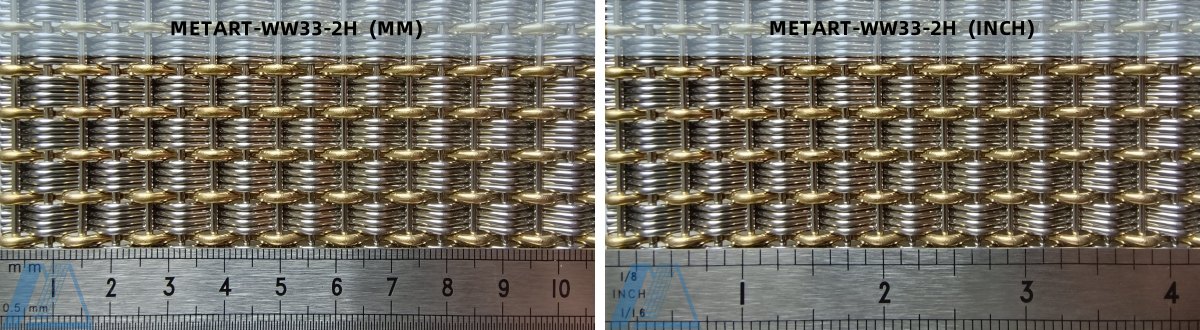

Diameters of Stainless Steel Wire rods |

1.45mm |

|

Diameters of Brass wires |

1.95mm |

|

Diameters of Wire Cluster |

4 pieces of 1.45mm |

|

Opening |

0mm |

|

Rod Pitch |

6mm |

|

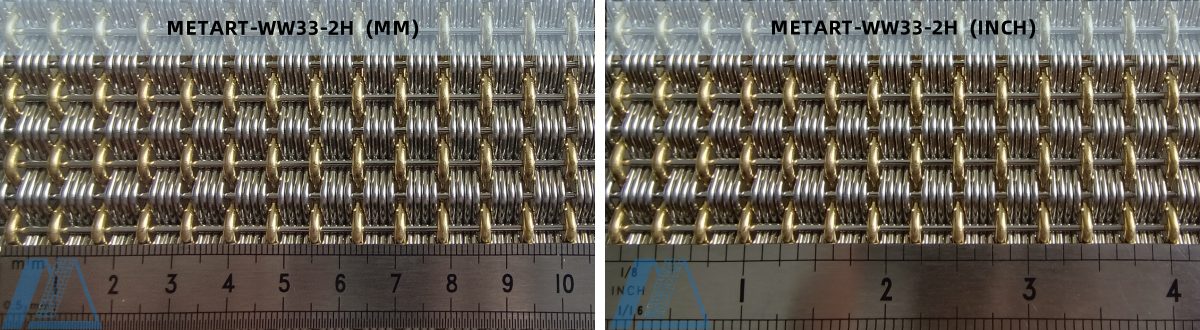

The overall thickness of the metal screen |

5.1mm (measure the highest point) |

|

Opening Area |

0% |

|

Privacy Rate |

100% |

|

Weight |

13.2kg/Square Meter |

|

Optional Finishes |

Mill Finish ( Original metal finish, not coating) |

Discover How "METART-WW33-2H" Decorative Metal Mesh is Manufactured

Selection of Premium Wires

From material grade selection to tensile strength control, METART BUILDING TECH has a strict QC system to remove bad wires. We only use premium AISI-grade stainless steel 304 or 316, and true brass wires. This makes sure the wire strength stays the same during weaving, so all wires have the same height after crimping into a decorative pattern. This is the key to weaving high-quality architectural wire mesh panels.

Pre-crimping of Wires before Weaving

The wires go through a crimping process with hardened alloy tooling. Different wires need different toolings. After crimping, we cut wires to size based on customer orders. Important: You must know which direction is the width of the decorative screen and which is the height. If not, a big mistake will happen.

Threading the Wires throughout the Heddles

Operators need to feed straightened stainless steel wire rods into the weaving heddles and then pull them through the weaving reed. This step requires a lot of patience. Workers must focus to avoid threading into the wrong heddle hole — if a wire is placed into the wrong position, every single wire must be pulled out and restarted.

Wire Weaving

After these decorative wires are properly positioned, the weaving process begins with feeding the weft wires following ISO 9044 and ASTM E2006 standards. A brass wire comes after every four 1.5mm crimped wires repeatedly until the required screen length is reached.

Here you can refer to the weaving video of our pattern code "METART-WW33-2", which is the same design made of stainless steel wires.

Break-down of METART-WW33-2H Decorative Metal Mesh

• Straightened Wire Rod: 1.5mm nominal diameter, actual measurement of 1.45mm

• 2mm nominal diameter decorative brass wires with an actual measurement of 1.95mm

• Wire cluster: 4 strands of 1.45mm architectural crimped wires

• Wire cluster: 4 strands of 1.45mm architectural crimped wires

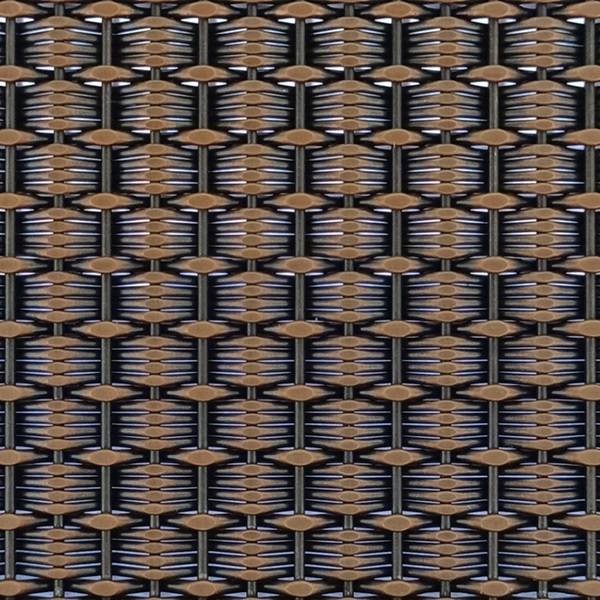

Application Beyond Lift / Elevator Interior Cladding

The application of METART-WW33-2H is not limited to lift car cladding, this decorative metal screen can be extended to the lobby cladding.

With its smart design and high-end look, it is beautifully suited for premium commercial cladding applications. Innovative decorative metal materials for high-end interiors will find METART-WW33-2H a sophisticated and highly flexible fin.

Whether in metal wall cladding applications feature walls or other architectural elements, this architectural design creates an original blend of elegance and strength that enhances any interior space.

Why Partnering with METART BUILDING TECH?

• Metart Building Tech is one of the leading decorative wire mesh manufacturers in China.

• An experienced OEM and ODM architectural wire mesh and service provider.

• Custom sheet size to meet different project requirements.

• Mini order accepted - No more MOQ. We can arrange production for you for any of your small projects.

Architectural Mesh Lift Interior Made of Decorative Wires

Woven Wire Mesh for Interior Claddings.

METART-WW37-2 Architectural Metal Mesh Cladding - Perfect decorative metal cladding for elevator interiors

Decorative Metals for Designers and Architects

Designer Metals for Interior Cladding and Decoration including elevator cabin & lobby interiors

METART-WW03, CLADDING WOVEN WIRE MESH

METART-WW03 Wire Mesh for Cladding

Lift Cabin Decorative Wire Mesh

METART-WW32-Lift Cabin Cladding Mesh

High Privacy Wire Mesh Screens, Privacy Decorative Metal Screen Infills Wire Strip 7x1mm

Architectural Metal Wire Mesh Panels for Privacy Screens - Antique Copper Finish- METART-WW02

©COPYRIGHT METART BUILDING TEC CO., LTD | ALL RIGHTS RESERVED | PRIVACY POLICY