.jpg)

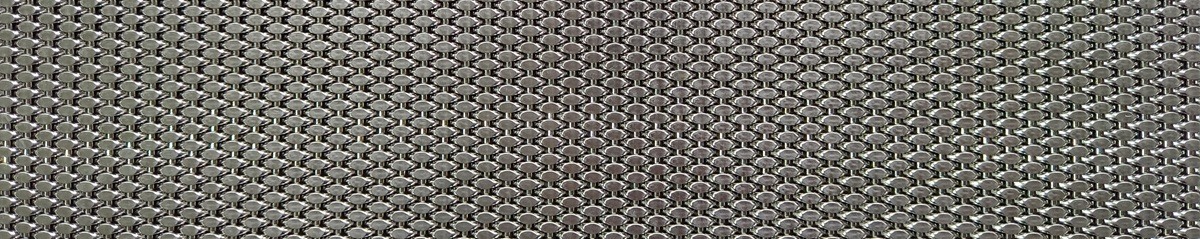

METART-WW32-Lift Cabin Cladding Mesh

Material: Stainless Steel 304 / Stainless Steel 316 / SS201

Type: Rigid Architectural Mesh

Opening Area: 0%

Weight: Approx 14.3kg/Square Meter

Finish: Mill Finish

Screen Width: up to 2000MM (need to suitable for international transporation)

Screen Length: up to 3000MM

GET A QUOTE

Lift Cabin Cladding Mesh

It always refers to decorative mesh panels used for interior wall cladding within lifts or elevators.

These panels are usually custom-cut to fit different lift designs and are most commonly made with woven wires and decorative crimped patterns.

Other architectural metal mesh options available on the market include woven strips and perforated metal panels, which can add distinct textures and visual appeal to lift interiors.

Discover How METART-WW32 Architectural Mesh Panels are Manufactured

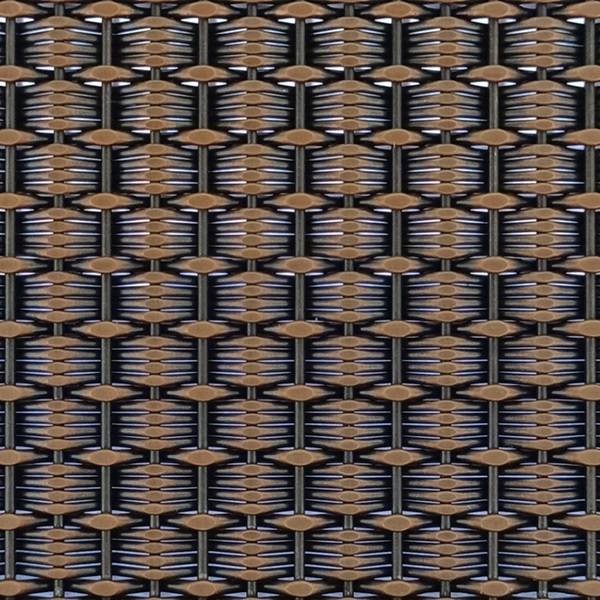

The METART-WW32 architectural mesh is crafted with precision, featuring a tightly woven structure. Vertically, it incorporates pre-straightened stainless steel wire rods with a nominal diameter of 1.5mm (actual measurement: 1.45mm), while horizontally, it uses decorative, pre-crimped wires with a nominal diameter of 2mm (actual measurement: 1.95mm).

This metal mesh is woven using the Plain Weave technique, but the specially designed decorative crimps result in a staggered architectural pattern that enhances its visual appeal. The outcome is an exceptionally smooth, flat surface on both sides of the panel.

Designed specifically for elevator cabin wall cladding, METART-WW32 is 100% non-transparent, making it ideal for applications that require full privacy.

Watch the video clip below to see how our loom performs the weaving process that brings this design to life.

Unique Elevator Cabin Wall Cladding:

The elevator cabin design is an essential aspect of modern building design, and wall cladding plays a significant role in enhancing the aesthetic appeal of elevator cabins.

Our METART-WW32 stainless steel decorative wire mesh pattern is a unique and innovative solution that offers privacy and visual appeal for elevator cabin wall cladding.

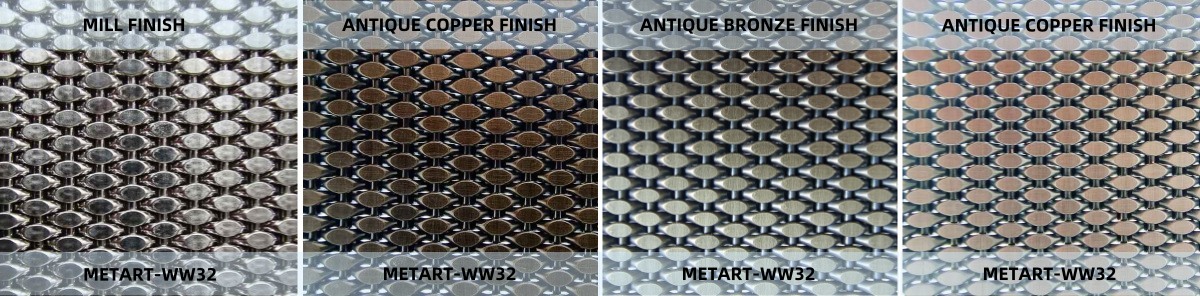

It is made from high-quality stainless steel wire rods and partially flattened staggered wires woven horizontally and vertically to create a visually appealing design. Here we will explore the benefits of using the customizable design while the METART-WW32 woven wire pattern may initially appear to feature a standard mill finish stainless steel surface, a mill finish is generally not recommended for direct wall applications due to unavoidable color variations in the wires.

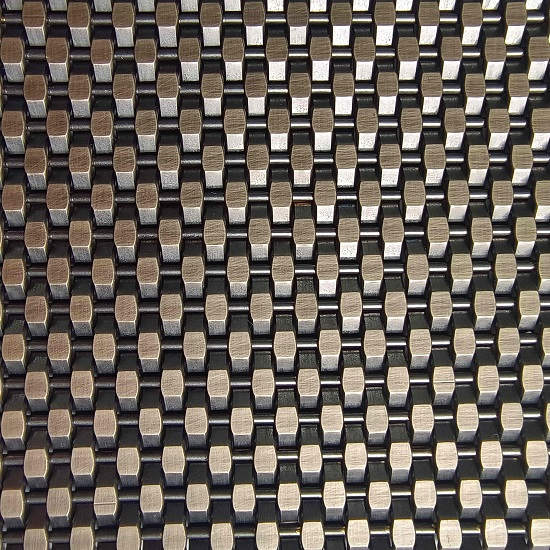

However, this mesh can be customized with a range of plating options, including brass plating, copper plating, titanium-based PVD plating, and additional antique treatment options, to meet diverse decorative requirements. These finishing options transform the standard mill finish into a visually stunning decorative wire mesh panel, providing architects and designers with endless possibilities to enhance the aesthetic appeal of elevator cabins, particularly in commercial settings.

Durability and Easy Maintenance

This architectural wall cladding stainless steel woven wire mesh pattern is a durable and long-lasting option for elevator cabin wall cladding.

Stainless Steel grade 304 is the number one used type of raw material and stainless steel 316 or 316L is a much higher-end level that is famous for its marine-grade corrosion resistance property.

Both of these 2 options are high-quality stainless steel, ensuring its structural integrity or exposure to harsh environmental conditions.

201-grade stainless steel is the cheapest stainless steel option, but it is not recommended for high-end wall cladding requirements.

It is only suitable after being plated, otherwise, it doesn't have much corrosion resistance function when compared with 304-grade stainless steel mesh, not to say 316 and 316L grade.

Additionally, its non-transparent design eliminates the need for regular cleaning of elevator cabin walls.

However, if cleaning is necessary, it is recommended to use a mild detergent solution, such as a mixture of warm water and mild dish soap.

Simply dampen a soft cloth or sponge with the solution and wipe down the surface of the mesh pattern, being careful not to use too much water, as excess water can potentially damage the stainless steel material. It is also recommended to avoid using abrasive cleaners or tools, such as steel wool or scouring pads, as they can scratch or damage the surface of the mesh pattern. After cleaning, the surface of the mesh pattern can be dried with a soft, dry cloth to prevent water spotting.

Versatility in Applications

While this architectural ornamental pattern is primarily designed for elevator cabin wall cladding, its unique design and quality materials make it a versatile option for a variety of other cladding applications such as shopping mall interior decoration, studio featured wall decorations, hotel lobby wall cladding, spa treatment rooms, or other commercial building spaces to provide ornaments or adding visual interest to the space.

Please refer to the following specification table

|

Pattern Code |

METART-WW32 |

|

Materials |

Stainless Steel 304 or 316, SS201 optional |

|

Type |

Rigid Architectural Mesh |

|

Wire Rod Diameter |

Nominal 1.5mm (1.45) |

|

Flattened Wire Diameter |

Nominal 2mm before flattened. (1.95) |

|

Wire Rod Pitch |

5mm |

|

Flatted wire pitch |

2mm |

|

Openings |

0mm |

|

The total thickness of the fabric |

3.5mm |

|

Opening Area |

0% |

|

Block out |

100% |

|

Privacy Rate |

100% |

|

Weight |

14.3kg/Square Meter |

|

Finish |

Stainless Steel Mill Finish. |

|

All optional ways of cut |

Straight Cut |

|

All optional Finishes |

Mill Finish ( Original stainless steel finish), Antique Copper plated, Antique Brass Plated, Titanium-Based PVD Plated |

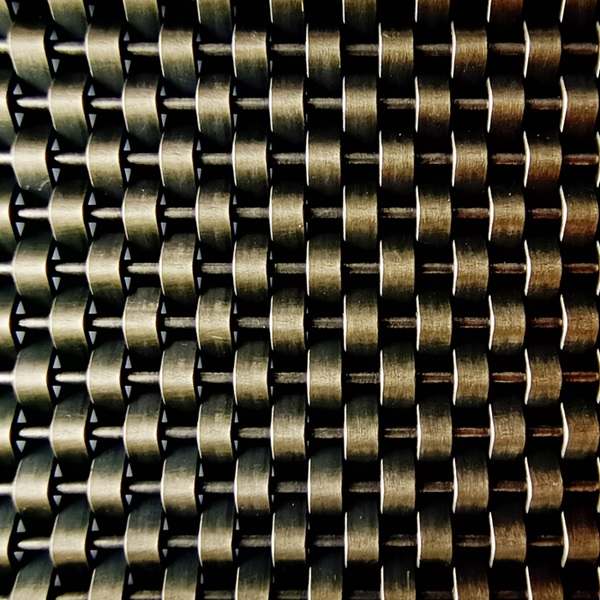

METART-WW04C412

Wire Mesh Elevator Cladding - choose a classy architectural metal screen panel

METART-WW32D Interior Cladding Wire Mesh made of stainless steel architectural wires

Woven Wire Mesh for Interior Claddings.

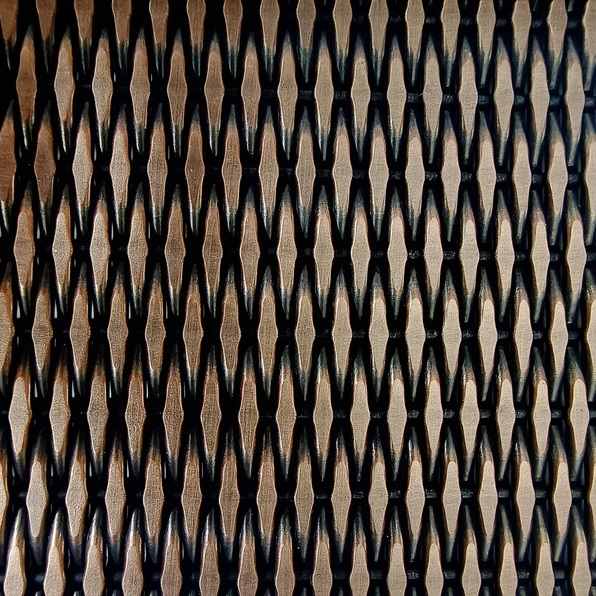

METART-WW37-2 Architectural Metal Mesh Cladding - Perfect decorative metal cladding for elevator interiors

Decorative Metals for Designers and Architects

Designer Metals for Interior Cladding and Decoration including elevator cabin & lobby interiors

METART-WW03, CLADDING WOVEN WIRE MESH

METART-WW03 Wire Mesh for Cladding

Stainless Steel Wall Cladding Wire Mesh Antique Bronze Finish for wall cladding.

Antique Bronze Finish Decor Wire Mesh for Commercial Interior Cladding

©COPYRIGHT METART BUILDING TEC CO., LTD | ALL RIGHTS RESERVED | PRIVACY POLICY