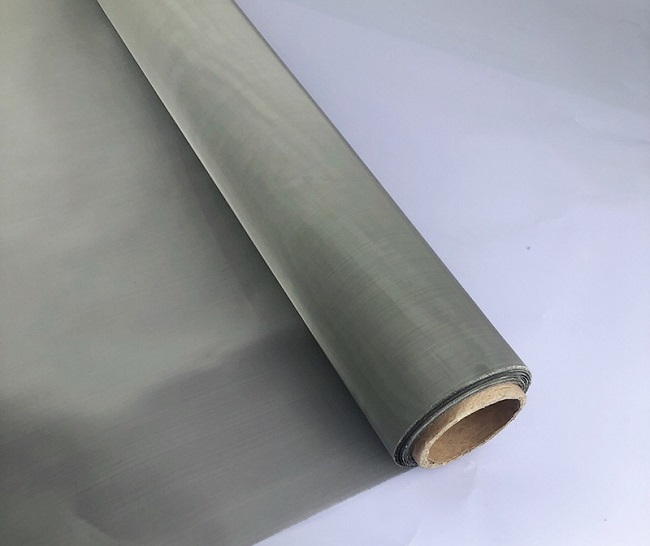

Inconel Wire Mesh's crucial attributes.

1. High Temperature Sustainability to Function

It is able to withstand greater than 1000 degree celcius without fainting making it ideal for industrial and high heat purposes.

2. Corrosion Resistance of the Greatest Level

Incredibly resistant to oxidation, acidic environments, and chemicals in seawater making it extremely favourable in marine and chemical arenas.

3. Greater Toughness and Sturdiness

Extracts from the surface microclimate have been presented as markers which help indicate the stresses and temperatures under which crystals interact.

4. Flexible Weaving Patterns

These patterns can be supplied in basic, twill or Dutch style weaves to suit particular industrial needs.

Applications of Inconel Wire Mesh In The Industry

1. Aerospace Industry

Jet engines, turbines, exhaust parts and heat shields must withstand tremendous thermal stresses, which make this material essential.

2. Chemical Processing

Used for filtering, supporting catalysts, and heat exchangers in strong corrosive environments.

3. Marine and Offshore Operations

It has excellent resistance to saltwater which is useful in oil rigs, desalination stations, and other underwater constructions.

4. Power Generation

High performance Inconel 625 is widely used in nuclear reactors and steam generators, where high operational temperatures are normal.

5. Automotive And Gas Turbines

Inconel parts can be used in manifolds turbocharger turbines and other highly stressed and heated mobile components.

Why Metart Building Tech is the Best For Inconel Wire Mesh?

Metart Building Tech is one of the best manufacturers of Inconel wire mesh of any type, for practically any industry. Their Inconel wire mesh products made with Nickel Alloy 600 (Inconel 600) Wire Mesh is specially manufactured with great care and accuracy which makes them stand out from the rest of the market.

Benefits of Metart Building Tech’s Inconel Wire Mesh

Metart Being the Industry Leader, the weave patterns on their Inconel wire mesh products do not suffer from loosening or wearing off due to the use of more advanced weaving machinery.

• Custom Fabrication - Different sizes of the mesh, wire diameters, and weaving styles are available as per the needs of the application.

• Strict Quality Assurance - Compliance with international standards ensures superior performance and reliability.

• Industry Expertise – Many years of experience delivering specialized solutions for critical industries.

Conclusion

Inconel wire mesh is ideal for industries that need materials that can withstand very high temperatures, heat, and pressure. For extreme industrial applications where durability, heat resistance, and corrosion protection are of utmost importance, this is the most dependable option.

Metart Building Tech, as a manufacturer, provides the industry with the best Inconel 600 wire mesh that goes beyond set standards.

Check out Metart Building Tech’s collection of nickel alloy 600 wire mesh and find the perfect solution for your industrial application.

+86 158 0318 7372 / +61 435 598 786

+86 158 0318 7372 / +61 435 598 786

.jpg)

+86 158 0318 7372 / +61 435 598 786

+86 158 0318 7372 / +61 435 598 786