Material: Steel, Stainless Steel, Aluminum, Super Alloy, Copper Alloy

Type of mesh: Unlimited, any type of metal mesh

Fabrication Types: Slitting, Cutting, punchings, welding, framing, etc.

Finishes: Cleaning, Passivating, Powder Coating, Painting, Plating.

GET A QUOTEWe produce a wide variety of custom wire mesh fabrications at METART BUILDIN TECH.

METART is an exporter and manufacturer of metal meshes. These are not just the wire mesh products but also the related accessories of these materials in various designs based on customer requirements within the global market.

Customization for woven and welded mesh involves mainly specifications and raw materials. Mild steel wires, stainless steel wires, aluminum wires, and galvanized wires, among others, are readily available in physical markets. However, for special alloy wires, we need to customize the wire rods and perform wire drawings to get them with the required diameter. Wire diameter and hole sizes are frequently specified by customers in order to limit their production activities. But in cases where clients fail to provide us with such specifications, we give them our standard ones or use their drawings together with samples as guides during the manufacturing process. Different sheet thicknesses can be chosen by our customers when ordering perforated metal sheets and expanded mesh; also hole diameters and pitch of holes may differ for these items. For decorative architectural metal meshes, you may modify wire diameters or opening size according to different projects.

Cutting-to-Size Service

We provide cut-to-size panels for wire meshes and sheet metals as well. Smaller panel sizes significantly reduce shipping costs specifically for air freight making deliveries faster as possible with this particular cutting service being done inside China’s leading wire mesh company resulting to lower costs overall. Some irregular shapes like circles or other exotic shapes often required including customizing punching dies based on specs and quantities or laser cutting.

Slitting Service

Wire mesh slitting refers to cutting up a wide roll of woven wire mesh into narrower strips that meet every specific requirement provided by a customer exactly as he wants it done anyway. Our slitting service provides perfect small rolls every time whether they are fine wire cloth used in delicate applications or wider strips of wide wire mesh we do every time we do slitting. We cut with pinpoint accuracy using our slitting machines and qualified personnel. Small custom wire mesh rolls are more convenient for end-users and customers with special needs, as they are easier to handle compared to large rolls.

Annealing Service

Annealing is an important process in the metal wire drawing industry that eliminates the internal strength of raw materials making them a pliable material for weaving into wire meshes. Annealing helps to relieve the inner tension and strength of wire cloth although it is not used very often in woven wire mesh production. This takes place within a vacuum furnace under either hydrogen or argon atmospheres. After annealing has been done on this type of wire cloth, it becomes softer which makes it ideal for deep-drawn woven wire products such as pleated wire mesh, custom wire mesh filter parts, deep-drawn wire mesh parts, and electronic wire cloth parts.

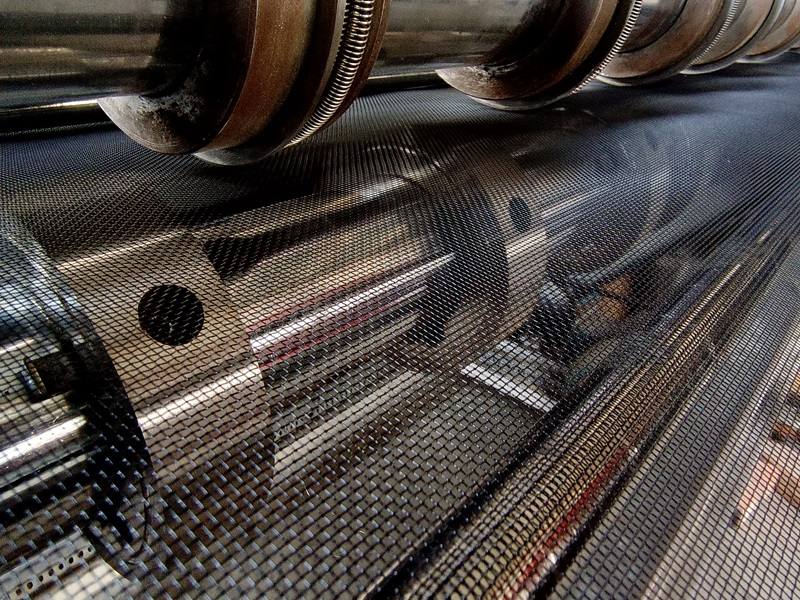

Calendering Service

Calendering enhances the properties of a woven mesh by refining them. The method involves pushing through calibrated pressure a woven mesh between rollers hence flattening the material while ensuring uniformity in terms of thickness and smoothness. Calendaring improves wear resistance, surface finish, and formability along with being versatile across

applications for calendered metal meshes. Our specialized calendering process optimizes performance while minimizing costs, providing a cost-effective solution for projects.

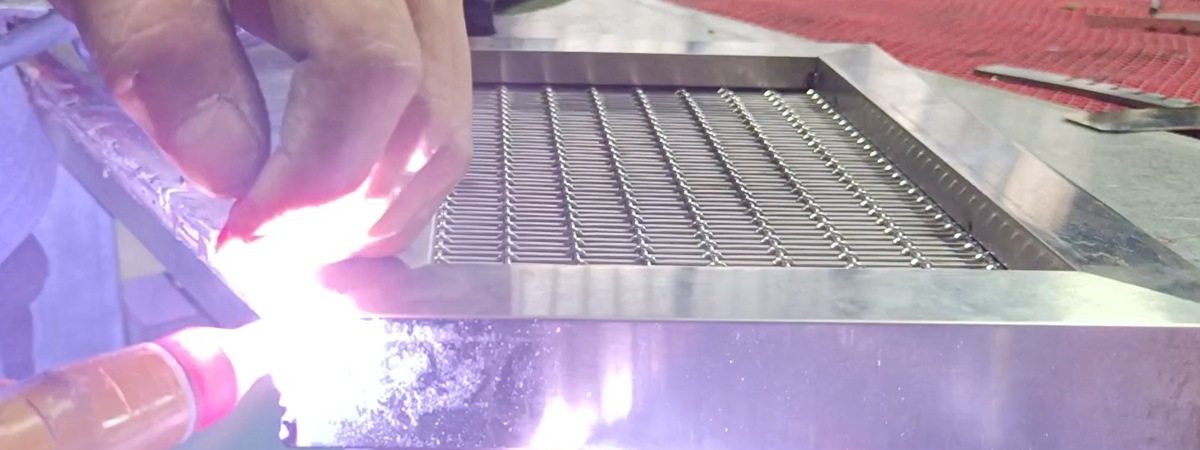

Custom Framing Service

Decorative wire mesh, in particular, needs frames. This will help you understand how the company provides various frameworks based on customers’ drawings such as u-channel frames, folded metal frames, and angle frames. Our framing solution guarantees durability and compatibility with different applications.

Various finishes

METART BUILDING TECH offers a range of finishes which include metals electroplating, galvanizing by hot dipping, powder coating, fluidized PVC coating, normal painting, PVDF painting, PVD plating, and Copper alloy plating. Every finish has unique material specifications and our customers are advised to contact us for advice on the right finish for their projects. Our wide array of finishes enables customers to achieve the required looks along with performance parameters in their wire mesh products.

Custom Wire Mesh Fabrication for Filter Elements

This involves the fabrication of wire mesh into different filter elements including wire mesh filter cylinders, multi-layer filter discs out of wire cloth or woven wire meshes, sintered wire mesh panels, and others like sintered wire mesh filters; candle filters; strainers; pleated wire mesh filters; porous sintered metal powder filters etc in METART. We have expertise in custom manufacturing that allows us to help a lot of industries meet their specific filtration needs while maximizing the efficiency and reliability of these very important devices.

If You Need Custom Wire Mesh Fabrication Manufacturers And Exporters Contact Us For Help

Pre-Crimped Woven Wire Mesh

Crimped Wire Mesh

2MM Decorative Wire Mesh with 13MM opening

Decorative Wire Mesh - An trending architectural wire mesh for interiors and exteriors - Get inspired right now.

welded wire mesh in stock and custom made

Stainless Steel Welded Wire Mesh

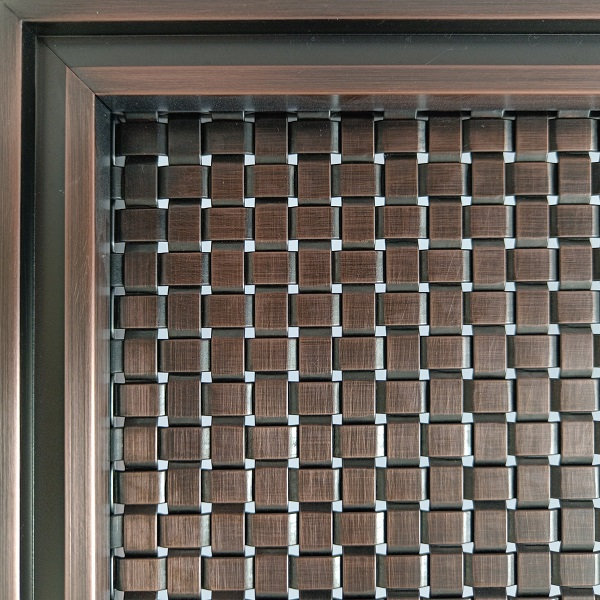

Framed partition wire mesh screen, the copper-finished one is a rendered image, not a real photo.

Framed Privacy Metal Screen-METART-WW02

Most Popular Material: AL Grade 3003, AL Grade 5052, Pre-Galvanized Steel Sheet.

Decorative Perforated Sheet

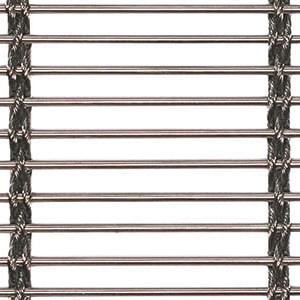

80/10 Car Park Cable Wire Mesh Rod Diameter / Rod Pitch: 3.0/10.0mm

METART-WWD06-80/10 Car Park Cable Wire Mesh

©COPYRIGHT METART BUILDING TEC CO., LTD | ALL RIGHTS RESERVED | PRIVACY POLICY