Post time: 02 22,2023

The Evolution of Wall Cladding Materials: From Mud and Straw to Architectural Metal Screens.

1. What is wall cladding?

Wall cladding refers to the process of layering a protective material on the exterior or interior walls of a building. The primary purpose of wall cladding is to protect the building structure from harsh weather conditions, temperature fluctuations, moisture, and other environmental factors. It can also be used for aesthetic purposes, adding visual appeal and architectural interest to a building's facade.

The materials used for wall cladding can vary depending on the location, the type of building, and the desired appearance. Some of the most common wall cladding materials include stone, brick, wood, metal, glass, and concrete. Each of these materials has unique properties that can affect their suitability for different building applications.

Stone and brick are popular materials for wall cladding due to their durability and ability to withstand harsh weather conditions. They are commonly used in historic buildings and traditional architecture, and their natural texture and color variations provide a classic, timeless appearance.

Wood is another popular choice for wall cladding, especially in colder climates. Wooden cladding provides a layer of insulation to a building, helping to regulate the internal temperature and improve energy efficiency. It also adds a natural, warm aesthetic to a building's exterior, and can be customized with different finishes and treatments to enhance its durability.

Metal cladding materials, such as stainless steel, aluminum, and copper, have become increasingly popular in contemporary building design due to their unique visual appeal, versatility, and durability. Metal cladding can be produced in a range of colors and finishes, and is often used to create sleek, modern facades that stand out in urban environments.

Glass cladding is another popular choice for building facades, offering a unique aesthetic and the ability to maximize natural light. Advances in glass manufacturing and technology have led to the development of tempered glass, double-glazed windows, and laminated glass, which provide additional insulation and durability to a building's envelope.

In addition to providing protection and visual appeal, wall cladding can also have a significant impact on the sustainability of a building. The choice of materials and installation techniques can affect a building's energy efficiency and environmental footprint, making it an important consideration for architects, builders, and property owners.

In summary, wall cladding is a critical component of building design and construction, providing protection from environmental factors and adding visual interest to a building's facade. The use of various materials, from traditional stone and brick to modern metal and glass, has allowed architects and builders to create unique and striking buildings that stand the test of time. The development of sustainable wall cladding materials and techniques is also an important consideration for those looking to reduce their environmental impact and create energy-efficient buildings for the future.

2. Ancient Mud and Straw Plaster Cladding Material

One of the earliest forms of wall cladding was mud and straw plaster, which was used in ancient Egypt and Mesopotamia. Mud and straw plaster was a mixture of mud or clay, straw, and water, and was applied to a woven lattice of sticks or reeds to create a protective layer on the exterior walls of buildings. The material was cheap and easy to obtain, as the mud was abundant in these regions, and had insulating properties that helped keep the interior of buildings cool in hot weather.

However, mud and straw plaster was not particularly durable and required frequent maintenance. It was susceptible to erosion from wind and rain, and could crack and crumble over time. To mitigate these issues, builders often added other materials, such as animal hair, dung, or lime, to the mixture to improve its durability and resistance to weather damage.

Mud and straw plaster was one of the earliest forms of wall cladding, dating back to ancient Egypt and Mesopotamia. The material was cheap and easy to obtain, but was not particularly durable and required frequent maintenance.

Despite its limitations, mud and straw plaster remained a popular wall cladding material for centuries, particularly in regions where the mud was abundant and other materials were scarce. The technique of applying mud and straw plaster to a woven lattice of sticks or reeds, known as wattle and daub, was used extensively in medieval Europe, and is still used in some parts of the world today.

3. Use of Stone and Brick Cladding

In medieval Europe, the use of stone and brick as wall cladding materials became increasingly popular due to their durability and ability to withstand harsh weather conditions. Stone was a particularly popular material due to its strength and resistance to weather damage. Medieval builders used a variety of different types of stone, including limestone, sandstone, and granite, to create protective layers on the exterior walls of buildings.

The Gothic architecture of the time featured elaborate stonework and decorative brick patterns, which served both functional and aesthetic purposes. Gothic cathedrals, for example, featured intricate stonework on their exteriors, with details such as gargoyles, ornate arches, and intricate reliefs. These details served both as decoration and as functional elements, such as drain spouts or structural support.

Using of stone and brick as wall cladding materials were not limited to religious or public buildings. Wealthy and powerful individuals or institutions also used these materials to make a statement about their status and prestige. Castles, manor houses, and other private residences often featured decorative stonework, such as towers, battlements, and ornate windows.

The use of stone and brick as wall-cladding materials in medieval Europe was a reflection of the power and wealth of the ruling class. These materials were difficult to obtain and expensive to work with, making them a symbol of power and prestige. However, they also served important functional purposes, such as protecting buildings from weather damage and providing additional insulation.

Generally saying, the use of stone and brick as wall cladding materials in medieval Europe was driven by their durability and ability to withstand harsh weather conditions. These materials were also used as a symbol of power and prestige, with ornate stonework and decorative brick patterns serving both functional and aesthetic purposes.

4. The use of wood cladding.

The use of wood as a wall cladding material dates back centuries, and has been particularly popular in regions where wood is abundant. In Scandinavia and northern Europe, wooden planks were used to create a protective layer on the building's exterior, and were often carved or painted to create decorative designs. This style of wall cladding was particularly popular in rural areas, where wood was readily available and served as a natural and affordable building material.

Wooden wall cladding continued to be used extensively in Tudor-style architecture during the Renaissance period. Tudor architecture, which emerged in England in the 16th century, was characterized by half-timbered construction and decorative wooden detailing. In this style of architecture, wooden beams and planks were used as both structural elements and decorative features, creating a unique and recognizable aesthetic.

The use of wood as a wall cladding material continued to be popular throughout the 19th and early 20th centuries, particularly in North America. Wooden shingles, clapboards, and board-and-batten siding were commonly used as protective layers on the exterior walls of houses and buildings. These materials were affordable and easy to work with, making them a popular choice for builders and homeowners alike.

However, the use of wood as a wall cladding material is not without its challenges. Wood is susceptible to weather damage and decay, and requires regular maintenance to prevent rot and insect infestations. In addition, wooden wall cladding can be a fire hazard if not properly treated with fire-retardant materials.

In recent years, the use of wood as a wall cladding material has been challenged by concerns over sustainability and environmental impact. While wood is a renewable resource, the demand for wood products has led to deforestation and habitat loss in many parts of the world. As a result, many architects and designers are turning to more sustainable and environmentally friendly wall cladding materials, such as metal cladding materials, which are both durable and recyclable.

While wood is a renewable resource, the demand for wood products has led to deforestation and habitat loss in many parts of the world. The production of wood products also contributes to greenhouse gas emissions and air pollution, particularly in regions where wood processing facilities are located.

In addition, the use of chemically treated wood products, such as pressure-treated lumber, can pose a risk to human health and the environment. These products are often treated with chemicals such as chromated copper arsenate (CCA) or ammoniacal copper zinc arsenate (ACZA) to prevent decay and insect damage. These chemicals can leach into the surrounding soil and groundwater, posing a risk to both human health and the environment.

The harvesting and processing of wood products also require significant amounts of energy and water. The use of heavy machinery, transportation, and processing facilities all contribute to carbon emissions and energy consumption. In addition, the use of water in the processing of wood products can lead to water pollution and depletion of freshwater resources.

In response to these concerns, many architects and designers are turning to more sustainable and environmentally friendly wall cladding materials. Metal cladding materials, such as stainless steel and aluminum, are becoming increasingly popular due to their durability, versatility, and modern aesthetic. These materials are also recyclable and can be used in a closed-loop system, reducing the amount of waste generated during the production process.

Other sustainable wall cladding materials include bamboo, cork, and recycled plastic. These materials offer similar benefits to metal cladding materials, including durability and versatility, while also being more environmentally friendly.

By making more environmentally conscious choices, we can reduce the impact of our built environment on the natural world.

5. The prototype of metal wall cladding material (Cast iron and steel wall cladding)

In the 19th and 20th centuries, advances in manufacturing and technology led to the development of new wall cladding materials, such as cast iron and steel which offered greater strength and durability than earlier materials, and allowed for more creative and innovative designs. Cast iron was often used for ornamental purposes, while steel was used in industrial and commercial buildings.

steel which offered greater strength and durability than earlier materials, and allowed for more creative and innovative designs. Cast iron was often used for ornamental purposes, while steel was used in industrial and commercial buildings.

Cast iron and steel are also some of the earliest metal materials used for wall cladding. Cast iron was commonly used in the 19th century for the exterior facades of commercial buildings in urban areas due to its durability and ornate details. The use of cast iron as a decorative element in architecture was especially prominent during the Victorian era, when cast iron was used extensively to create elaborate facades, cornices, and other decorative features.

Steel also became a popular wall cladding material in the early 20th century, particularly in the form of corrugated steel sheets. These sheets were used to create a protective layer on the exterior walls of industrial buildings, such as warehouses and factories, especially after the steel is perforated or punched into regular hole patterns. Steel was a particularly popular material for these applications due to its strength and durability, which helped protect buildings from weather damage and wear and tear from industrial use.

Today, metal wall cladding materials have continued to evolve and expand, with new technologies and materials offering even greater durability and versatility. Stainless steel, aluminum, and galvanized steel are some of the most popular metal cladding materials used today, and are used in a wide variety of applications, from high-rise office buildings to single-family homes. These materials are prized for their durability, low maintenance requirements, and aesthetic appeal.

6. Concrete and Masonry Cladding.

The 19th and 20th centuries saw a rise in the popularity of concrete and masonry as wall cladding materials, due to their increased durability, versatility, and strength made possible by advances in manufacturing and technology. These materials offered increased durability, versatility, and strength, and quickly became popular choices for builders and architects.

Concrete is a composite material made up of cement, water, and aggregate, such as sand, gravel, or crushed stone. The use of concrete as a wall cladding material dates back to ancient Rome, where it was used extensively in the construction of buildings and infrastructure. In modern times, concrete has been used to create a wide range of wall cladding products, such as precast concrete panels, concrete blocks, and tilt-up walls. These products offer a high degree of flexibility in terms of design and construction, allowing for the creation of complex shapes and patterns.

Masonry is a term used to describe any building material made from bricks, stones, or concrete blocks. The use of masonry as a wall cladding material dates back to ancient civilizations, such as the Egyptians and Babylonians, who used stones to create protective layers on their buildings. In modern times, masonry is used to create a wide range of wall cladding products, such as brick veneer, stone veneer, and concrete masonry units. These products offer a high degree of durability, fire resistance, and weather protection, making them a popular choice for commercial and industrial buildings.

The use of concrete and masonry as wall cladding materials offers a number of advantages over traditional materials such as wood and plaster. Concrete and masonry materials are highly durable, and can withstand harsh weather conditions, impact, and wear and tear. They also provide excellent insulation, helping to regulate temperature and reduce energy costs. In addition, these materials are fire-resistant, making them a popular choice for commercial and industrial buildings.

The development of concrete and masonry materials has led to a wide range of new products and techniques for wall cladding. For example, precast concrete panels can be made in a factory and then transported to a building site for installation, reducing construction time and labor costs. Similarly, thin brick and stone veneer products offer the look of traditional masonry materials at a fraction of the weight and cost.

In recent years, the development of new technologies and materials, such as fiber-reinforced concrete and insulated concrete forms, has further expanded the possibilities for concrete and masonry as wall cladding materials. These materials offer even greater durability, insulation, and versatility, and are increasingly popular for both commercial and residential buildings.

Concrete and masonry materials have a long history as wall cladding materials, dating back to ancient civilizations. Today, these materials continue to be popular choices for their durability, fire resistance, insulation, and versatility. The development of new technologies and materials has led to a wide range of new products and techniques, further expanding the possibilities for concrete and masonry as wall cladding materials.

7. The use and development of glass cladding material.

Besides, concrete and bricks, glass also become an increasingly popular material for use in building cladding projects. From historic landmarks to modern skyscrapers, glass has been used to create stunning building facades around the world. The development and use of glass in building cladding have come a long way since its early use in ancient Roman architecture.

One of the earliest examples of glass being used in building cladding can be found in the Roman Coliseum. The amphitheater was constructed with translucent glass windows that allowed light to filter through while protecting spectators from the elements. This early use of glass in building construction paved the way for its use in building cladding.

In the early 20th century, advancements in glass manufacturing and technology led to the development of new types of glass that could be used in building construction. One of the most significant breakthroughs was the development of tempered glass, which is heated and cooled rapidly during production, making it stronger and more durable than traditional glass. This made tempered glass an ideal material for building cladding, as it was able to withstand harsh weather conditions and provide a high degree of protection against the elements.

Another important development in glass cladding was the use of double-glazed windows, which feature two panes of glass with a layer of air or gas in between. This layer of insulation helps reduce energy costs by providing an additional layer of thermal insulation to the building envelope. This has made glass cladding a popular choice for green building projects, as it can help reduce the carbon footprint of a building and increase its energy efficiency.

The use of laminated glass has also become popular in building cladding. Laminated glass is created by bonding two or more layers of glass with a layer of plastic, creating a material that is both strong and shatterproof. This has made laminated glass an ideal choice for building cladding in areas that are prone to high winds, as it can provide a high degree of protection against impact.

The use of glass in building cladding has continued to evolve with the development of new technologies and manufacturing processes. Modern glass cladding can be produced in a range of colors and finishes, providing a high degree of customization and flexibility in terms of design and construction. Additionally, new advances in glass coatings and materials have increased the durability and strength of glass cladding, making it an ideal choice for a wide range of building applications.

One notable example of the use of glass cladding in a building project is the Burj Khalifa in Dubai. This iconic skyscraper features over 26,000 glass panels that were specifically designed to withstand the extreme heat and wind conditions of the region. The glass cladding was produced using a specialized manufacturing process that involved the use of high-strength glass and advanced coatings to increase its durability and resistance to weathering.

The use of glass cladding has also become popular in green building projects. The HSB Turning Torso building in Sweden, for example, features a stunning glass facade that maximizes natural light while minimizing the building's carbon footprint. The glass cladding was specifically designed to provide a high degree of insulation and energy efficiency, helping to reduce the building's overall energy consumption.

Anyway, glass has become an increasingly popular material for building cladding due to its unique visual appeal, versatility, and durability. The development and use of tempered glass, double-glazed windows, laminated glass, and other new technologies and manufacturing processes have increased the strength and functionality of glass cladding. This has made it an ideal choice for a wide range of building applications, from historic landmarks to modern skyscrapers. The ability of glass cladding to provide energy efficiency, durability, and visual appeal makes it an ideal choice for green building projects and a popular option for.

7. The rise of metal cladding material in buildings.

More recently, the use of metal cladding materials, such as aluminum and stainless steel, has gained popularity due to their durability, versatility, and modern aesthetic. These materials are often used in contemporary architecture and design, where they can be shaped and formed into intricate and unique designs. Metal cladding is also often used in high-rise buildings, where it can withstand harsh environmental conditions and provide an additional layer of insulation.

While materials such as stainless steel mesh, aluminum mesh, and other sheetmetal products including perforated aluminum, perforated stainless steel, architectural expanded aluminium screen, laser cut corten steel, laser cut aluminium panels have gained popularity in recent years, one material that has seen a decline in usage is aluminum-plastic panels.

8. Aluminum-Plastic Panels and Fire Safety: Lessons Learned from the Grenfell Tower Tragedy

In June 2017, a deadly fire broke out in Grenfell Tower, a high-rise apartment building in London, UK. The fire quickly spread through the building's exterior cladding, which was made up of aluminum-plastic panels, or ACM panels, and insulation material. The fire resulted in 72 deaths and more than 70 injuries, making it one of the deadliest building fires in the UK in decades.

exterior cladding, which was made up of aluminum-plastic panels, or ACM panels, and insulation material. The fire resulted in 72 deaths and more than 70 injuries, making it one of the deadliest building fires in the UK in decades.

The use of ACM panels in building facades had been a common practice for many years, as they were lightweight, low cost, and easy to install. However, in the wake of the Grenfell Tower tragedy, it became clear that these panels posed a significant fire safety risk. The panels were found to have contributed to the rapid spread of the fire, allowing it to move quickly through the building's exterior and reach upper floors. The insulation material behind the panels was also found to have contributed to the fire's intensity.

In the months following the tragedy, investigations revealed that the ACM panels used in Grenfell Tower were highly flammable and did not meet fire safety standards. This led to a global reassessment of building materials, including the use of ACM panels in building cladding and decoration. Many countries and regions have since updated their building codes and regulations to restrict or ban the use of ACM panels in building facades.

For example, in the United Kingdom, new regulations were introduced in December 2018 that ban the use of ACM panels in new buildings taller than 18 meters. The regulations also require the removal of ACM panels from existing buildings if they do not meet certain fire safety standards. Other countries, such as Australia, Germany, and the United States, have also updated their building codes and regulations to restrict or ban the use of ACM panels in building cladding and decoration.

In response to the increased scrutiny of ACM panels, many architects and designers are now turning to safer and more sustainable metal cladding materials, such as stainless steel and aluminum wire mesh. These materials offer similar aesthetic and design flexibility as ACM panels, but with greater fire safety and durability.

9. Regular Stainless Steel Crimped Wire Mesh used for contemporary wall cladding panels.

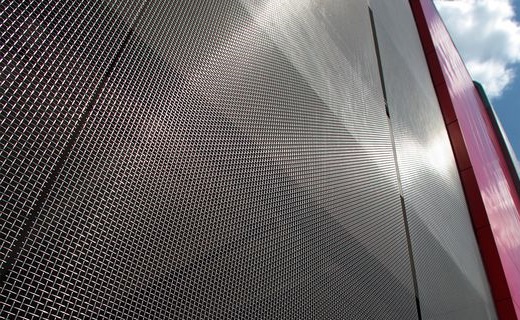

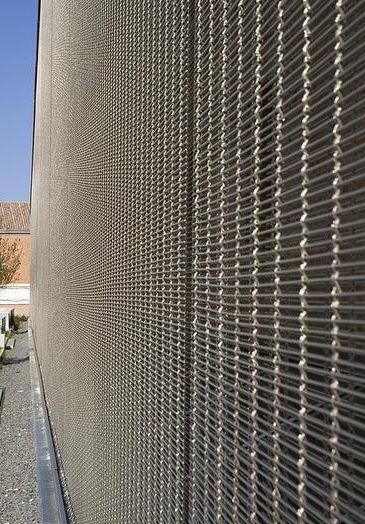

Stainless steel crimped wire mesh is a versatile material that is increasingly used in contemporary wall cladding panels. This type of wire mesh is made from high-quality stainless steel wire, which is crimped to form a tightly woven mesh pattern. The resulting mesh is both strong and durable, making it an ideal material for use in wall cladding panels.

Stainless steel crimped wire mesh is prized for its aesthetic appeal, as well as its practical benefits. The mesh pattern can be used to create a variety of designs and textures, and is often used to create striking visual effects on building facades. In addition, the mesh pattern can provide additional ventilation and natural light to the interior of a building, making it a popular choice for large commercial and industrial buildings.

designs and textures, and is often used to create striking visual effects on building facades. In addition, the mesh pattern can provide additional ventilation and natural light to the interior of a building, making it a popular choice for large commercial and industrial buildings.

The use of stainless steel crimped wire mesh in wall cladding panels also offers a number of practical benefits. The mesh pattern allows for the free flow of air and moisture, which can help to regulate temperature and prevent the buildup of condensation. This can be particularly important in humid or wet environments, where traditional cladding materials may be more prone to moisture damage.

Stainless steel crimped wire mesh is also highly durable and resistant to weather and wear and tear. It is not susceptible to rust or corrosion, making it ideal for use in harsh outdoor environments. In addition, the wire mesh can be coated with a variety of finishes, such as epoxy or powder coating, to provide additional protection against corrosion and other forms of damage.

Overall, stainless steel crimped wire mesh is a versatile and practical material that is increasingly used in contemporary wall cladding panels. Its strength, durability, and aesthetic appeal make it a popular choice for a wide range of building applications, from commercial and industrial buildings to residential homes.

10. Architectural Stainless Steel Wire Mesh and Decorative aluminum wire mesh in building wall cladding.

Architectural stainless steel wire mesh and decorative aluminum wire mesh are two of the most popular materials used in contemporary building wall  cladding. These materials offer a range of benefits, including durability, versatility, and aesthetic appeal, and are increasingly used in both commercial and residential building projects.

cladding. These materials offer a range of benefits, including durability, versatility, and aesthetic appeal, and are increasingly used in both commercial and residential building projects.

Architectural wire mesh is typically made from high-quality stainless steel wire and other alloy wire mesh. The mesh is carefully woven into a unique and visually stunning pattern, creating a strong and flexible material that can be used in a wide range of applications. This type of wire mesh is often used to create one-of-a-kind building facades that are both striking and practical.

Architectural stainless steel wire mesh is often used to create a variety of textures and designs in building wall cladding. The mesh pattern can be used to create intricate and visually stunning facades, providing a modern and contemporary look that is both eye-catching and practical. The mesh can also be used to provide ventilation and natural light to the interior of a building, making it a popular choice for large commercial and industrial buildings.

The benefits of architectural wire mesh extend beyond its aesthetic appeal. It is highly durable, resistant to weather and wear and tear, and provides excellent insulation properties. The mesh pattern can help to regulate temperature and prevent the buildup of condensation, making it a practical choice for a wide range of building applications.

Decorative aluminum wire mesh is another popular material used in building wall cladding. It is lightweight, durable, and can be easily formed into a variety of patterns and designs. Decorative aluminum wire mesh is often used to create visually stunning facades that provide both aesthetic appeal and practical benefits, such as ventilation and natural light.

In conclusion, architectural stainless steel wire mesh and decorative aluminum wire mesh are two popular materials used in contemporary building wall cladding. These materials offer a range of benefits, including durability, versatility, and aesthetic appeal, and are increasingly used in both commercial and residential building projects. The unique and visually stunning patterns of architectural wire mesh can help to create one-of-a-kind building facades, while also providing practical benefits such as ventilation and natural light. Whether used in combination with other building materials or as a standalone feature, architectural wire mesh is a versatile and practical choice for building wall cladding.

11. Perforated sheet in wall cladding

Perforated sheet metal is a popular material used in contemporary wall cladding. It offers a range of benefits, including visual appeal, practicality, and versatility, and is used in a variety of commercial and residential building projects.

Perforated sheet metal is created by punching or drilling a series of holes in a flat sheet of metal, creating a mesh-like pattern. The size a nd pattern of the holes can be customized to create a variety of designs and textures, offering a high degree of flexibility in terms of design and construction.

nd pattern of the holes can be customized to create a variety of designs and textures, offering a high degree of flexibility in terms of design and construction.

Perforated aluminum, perforated stainless steel, and perforated galvanized sheet are some of the most common types of perforated sheet metal used in wall cladding. These materials offer a range of benefits, including high durability, corrosion resistance, and the ability to withstand harsh weather conditions. In addition, they can be coated with a variety of finishes, such as powder coating, PVDF coating, copper plating, brass plating, and PVD titanium plating, to provide additional protection against corrosion and other forms of damage.

Perforated aluminum is a lightweight and durable material that is well-suited for use in building wall cladding. It is often used in modern and contemporary buildings, as it can be formed into a variety of unique shapes and designs, creating a visually stunning effect. Perforated aluminum is also easy to install and maintain, making it a practical choice for a range of building applications.

Perforated stainless steel is a strong and durable material that is often used in building wall cladding. It is resistant to corrosion and can withstand harsh weather conditions, making it an ideal material for outdoor applications. Perforated stainless steel can be used to create a variety of designs and textures, and is often used to create visually interesting building facades that are both striking and practical.

Perforated galvanized sheet is a versatile material that is commonly used in building wall cladding. It is made from high-quality steel that has been coated with a layer of zinc, providing additional protection against corrosion and other forms of damage. Perforated galvanized sheet is often used in industrial and commercial buildings, where its strength and durability make it an ideal material for use in harsh environments.

One of the main advantages of perforated sheet metal in wall cladding is its visual appeal. The mesh pattern can be used to create a variety of textures and designs, and can be used to create stunning visual effects when paired with lighting or other design elements. Perforated sheet metal can also be used to provide additional ventilation and natural light to the interior of a building, making it a popular choice for large commercial and industrial buildings.

Powder coating and other plating technologies are often used to enhance the visual appeal of perforated sheet metal in wall cladding. These finishes can be used to add color and texture to the metal, creating a unique and visually stunning effect. They can also be used to protect the metal against corrosion and other forms of damage, increasing the durability and lifespan of the material.

As a cladding material, 304 grade stainless steel can be used for interior wall decoration due to its high resistance to corrosion and durability. However, for exterior cladding projects, it is recommended to use ss316, which is a marine grade stainless steel that offers even greater resistance to corrosion and can withstand harsh weather conditions. For perforated aluminum, grade 5052 is a popular choice for exterior wall cladding due to its high resistance to corrosion and ability to withstand exposure to saltwater. This is particularly important in coastal areas where saltwater can cause corrosion and other forms of damage to building materials.

In summary, perforated sheet metal is a versatile and practical material that offers a range of benefits for building wall cladding. By selecting the appropriate material and finish for a project, perforated sheet metal can be used to.

12. Laser Cut Aluminum Sheet and Laser Cut Corten Steel in Wall Cladding.

Laser cut aluminum is a popular material used in contemporary wall cladding. It offers a range of benefits, including visual appeal, practicality, and versatility, and is used in a variety of commercial and residential building projects.

Laser cutting is a precise and efficient process that uses a high-powered laser beam to cut through the material, creating a variety of shapes and designs. This process allows for a high degree of customization and flexibility, making it an ideal choice for creating unique and visually stunning building facades.

Aluminum is a lightweight and durable material that is well-suited for use in building wall cladding. It is often used in modern and contemporary buildings, as it can be formed into a variety of unique shapes and designs, creating a visually stunning effect. Laser cut aluminum sheet is also easy to install and maintain, making it a practical choice for a range of building applications.

Laser cut aluminum panels can be used to create a variety of designs and patterns, offering a high degree of flexibility in terms of design and construction. The process allows for precise cuts and intricate detailing, making it an ideal choice for creating custom designs and patterns that are unique to a specific project.

One of the main advantages of laser cut aluminum screen panel in wall cladding is its visual appeal. The precision cuts and intricate detailing create a stunning visual effect that can be used to create a variety of textures and designs. When paired with lighting or other design elements, laser cut aluminum can create stunning visual effects that enhance the overall aesthetic of a building.

In addition to its visual appeal, laser cut aluminum screen panels in wall cladding offers practical benefits as well. It is lightweight and easy to install, making it a popular choice for a wide range of building applications. It is also durable and requires minimal maintenance, making it a cost-effective choice for long-term projects.

Powder coating and other finishes can be used to enhance the visual appeal of laser cut aluminum in wall cladding. These finishes can be used to add color and texture to the material, creating a unique and visually stunning effect. They can also be used to protect aluminum against corrosion and other forms of damage, increasing the durability and lifespan of the material.

Finally, we would say, laser cut aluminum is a versatile and practical material that offers a range of benefits for building wall cladding. By using this material in building projects, architects and designers can create visually stunning and durable building facades that are both functional and aesthetically pleasing.

13. Perforated Corten Steel Sheet and Laser Cut Corten Steel Sheet in exterior Wall Cladding Projects.

For some countries and areas, Corten steel has become a popular choice for exterior wall cladding due to its unique aesthetic and durability in harsh weather conditions. Perforated Corten steel sheet and laser cut Corten steel sheet are two types of Corten steel that have gained popularity for their ability to create visually interesting and long-lasting building facades.

Perforated Corten steel sheet is created by punching a series of holes in a flat sheet of the material, creating a mesh-like pattern. The size and pattern of the holes can be customized to create a range of designs and textures, offering a high degree of flexibility in terms of design and construction. This perforation pattern can also be used to control the amount of sunlight that enters a building, making it an ideal material for solar control and shading projects.

Laser cut Corten steel sheet is created by using a high-powered laser beam to cut through the material, creating a range of shapes and designs. The precise cuts and intricate detailing can be used to create striking visual effects when combined with lighting or other design elements. This flexibility and customization make it an ideal choice for creating unique and visually stunning building facades.

Both perforated Corten steel sheet and laser cut Corten steel sheet offer a range of benefits, including high durability, corrosion resistance, and the ability to withstand harsh weather conditions. The use of powder coating and other plating technologies can enhance the visual appeal of these materials, adding color and texture to the material and protecting it against corrosion and other forms of damage.

Perforated Corten steel sheets and laser-cut Corten screens are also used in solar control and shading projects. These materials can create a range of different opening areas by percentage, allowing designers to control the amount of sunlight that enters a building. This feature can help reduce energy costs by providing natural lighting while minimizing the amount of heat that enters a building.

Generally speaking, perforated Corten steel sheets and laser-cut Corten steel screens are popular materials used in contemporary exterior wall cladding projects. These materials offer high a high degree of customization and flexibility, making them ideal for creating unique and visually stunning building facades. Their durability and ability to withstand harsh weather conditions make them a practical choice for a wide range of building applications. Additionally, their ability to control the amount of sunlight that enters a building makes them an ideal material for solar control and shading projects.

14. The use of the architectural expanded aluminum screen in exterior wall cladding.

Besides perforated panels, expanded aluminum panels also have become a popular choice for building cladding due to their unique properties and aesthetic appeal. The panels are made from sheets of aluminum that are cut and stretched to create a three-dimensional mesh-like pattern. This process makes the aluminum panels lightweight, durable, and strong, allowing them to withstand harsh weather conditions and other environmental factors.

Expanded aluminum panels can be produced in a range of sizes and shapes, providing a high degree of customization and flexibility in terms of design and construction. They can be finished in a variety of colors and textures, making them a popular choice for architects and builders who want to create a striking and unique building facade.

One of the primary benefits of using expanded aluminum panels for wall cladding is their ability to provide a high degree of ventilation and light transmission. The perforated pattern of the panels allows air and light to flow through, helping to regulate the internal temperature and improve energy efficiency. This can be especially beneficial in hot and humid climates where air circulation is essential for building occupants' comfort.

In addition to their functional properties, expanded aluminum panels can also provide an aesthetically pleasing appearance to a building's exterior. The unique three-dimensional pattern of the panels can create a dynamic, textured effect that can be used to enhance the building's architectural design. The panels can also be used in conjunction with other cladding materials, such as glass or stone, to create a striking contrast and visual interest.

Expanded aluminum panels are also easy to install, making them a popular choice for both new construction and renovation projects. The panels can be cut and shaped to fit any building surface and can be easily attached using a range of installation techniques, including mechanical fasteners, adhesive bonding, or interlocking systems.

Finally, expanded aluminum panels have become a popular choice for building cladding due to their unique properties, versatility, and aesthetic appeal. Their ability to provide ventilation and light transmission, as well as their lightweight and durable construction, make them an ideal choice for a wide range of building applications. As building design and construction continue to evolve, expanded aluminum panels are likely to remain a popular choice for architects and builders looking to create striking and sustainable building facades.

©COPYRIGHT METART BUILDING TEC CO., LTD | ALL RIGHTS RESERVED | PRIVACY POLICY