Post time: 07 30,2025

Supplier Selection, Quality, and Uses of Crimped Wire Mesh Manufacturers

Wire strands are used to make crimped wire mesh, commonly known as square wire mesh. Wire mesh is composed  of wires that run parallel to the roll's length (line wires) and width (cross wires). The line and cross wires are braided together. In other words, the wires pass beneath and over one another.

of wires that run parallel to the roll's length (line wires) and width (cross wires). The line and cross wires are braided together. In other words, the wires pass beneath and over one another.

Various forms of wire mesh weaving are possible based on the aperture size, wire diameter, and type of material. Wire Mesh Crimped Crimped wire mesh is simply woven with pre-crimped wire so that there is space between the wires to be cleaned, and it does not lock up so tightly that it is very difficult to maintain clean.

Crimped wire mesh producers cannot downplay the importance of offering standard yet customized products, given the growing demand for premium mesh materials for both industrial and aesthetic purposes.

Crimped Wire Mesh: What Is It?

Before the wire is woven into a net, it is pre-crimped to create crimped wire mesh. This junction pre-crimping creates a structural link and allows wires to lock together securely at intersections. Crimp wire mesh is also frequently woven using materials including plain steel, high carbon steel, and various stainless steel, like AISI 304, 316, 321, 310S, etc.

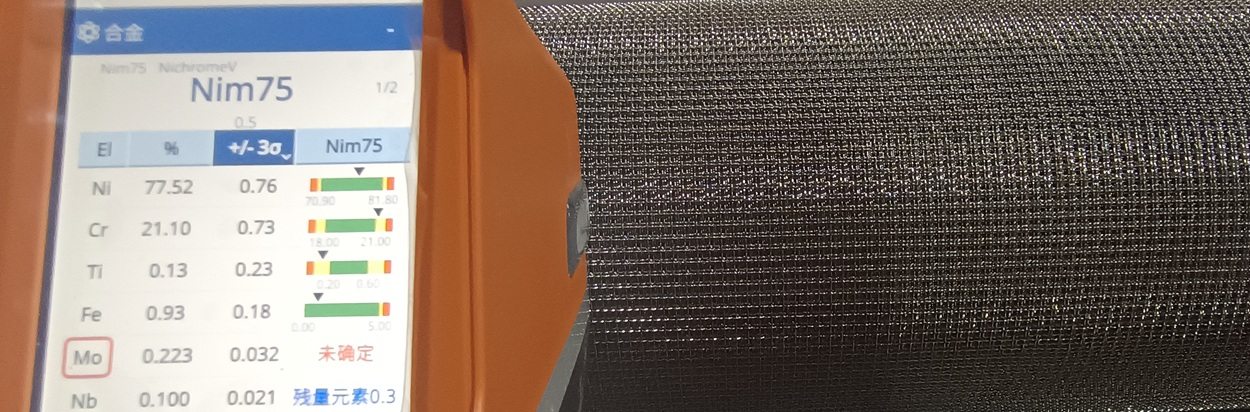

For special and harsh environments, different super alloys can be made into crimped wire mesh, including Nichrome 80/20 crimped wire mesh, Monel 400 wire mesh, Inconel wire mesh, 904L crimped wire mesh panels, and duplex steel wire mesh. The wire diameters and opening sizes can be flexibly customized based on customers' requirements.

Typical kinds include:

A general-purpose crimp that is frequently utilized in lighter applications is the straight crimp.

• Inter Crimp: These crimps are positioned between to allow for a tighter weave.

• Lock Crimp: This keeps wires from coming loose by securing them in place.

• Flat Top Crimp: For flat surfaces used in architecture

Utilizing Crimped Wire Mesh in Applications

Crimped wire mesh is widely used in numerous sectors because it strengthens a product's edges and increases its durability. Among the important uses are:

• Mining, Quarrying – Used as transition materials for vibrating screens and sieves.

• Building – Reinforcement, fencing, and safety barriers.

• Agriculture – Protecting crops, enclosures for animals, and grain storage.

• Food Processing – Wicking and Filtering: Sieves, drying trays, mats, and grills.

• Building and construction -Panelling, profiles, and interior finish.

Additionally, manufacturers can customize wire thickness, aperture size, and material grade to meet the unique industry needs of their clients.

Crucial Elements of Reputable Crimped Wire Mesh Providers

When deciding who to collaborate with, there are additional factors to take into account besides cost.

What Qualities Are Needed by Leading Manufacturers of Crimped Wire Mesh?

1. Material Quality: Fittings of superior quality are made to withstand wear and corrosion.

2. Uniformity and strength are ensured by 100% accuracy in weave and crimp. Custom size, mesh count, and quality that is comparable to that of the least expensive manufacturer.

3. Standards Compliance: Produce goods in accordance with global production guidelines (ISO, ASTM).

4. On-time Delivery & Support: Expert technology support, specialized logistics, and after-sales service teams are crucial.

World's Finest Crimped Wire Mesh Manufacturing

• China: One of the top exporters, offering a wide range of affordable options.

• India: Known for its competitive pricing and high-quality handiwork.

• Germany and the USA: Leaders in performance industrial mesh and precision weaving.

• Japan: Leading producer of advanced technology and materials resistant to corrosion.

The scale of the project, financial limitations, and customization needs all influence the choice of supplier or nation.

How to Pick the Best Manufacturer of Crimped Wire Mesh

• Test Product Samples: Make sure to request samples in order to evaluate the material and weave quality.

• Verify Certification: ISO and other standards address consistency and dependability.

• Assess Manufacturing Capability: The project's scalability guarantees on-time delivery and the availability of bulk orders.

• Verify References: Customer reviews offer more information about dependability.

• Examine technical specifications; don't cut corners on wire diameter, mesh count, or material tensile strength in order to save money.

In conclusion

Manufacturers of wire mesh are essential to a number of sectors where durability, strength, and accuracy are paramount. They are a low-cost, high-performing piece of equipment that is assured to survive for many years, whether they are employed for mining screens or architectural facades. In order to get the most out of your facilities for many years to come, evaluate your suppliers for technical know-how, product operability, and service support.

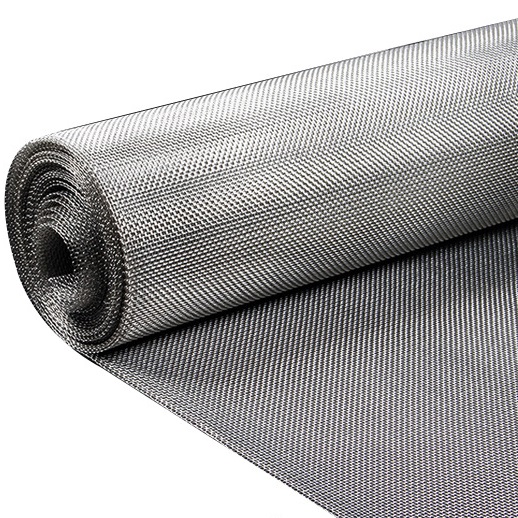

Pre-Crimped Woven Wire Mesh

Crimped Wire Mesh

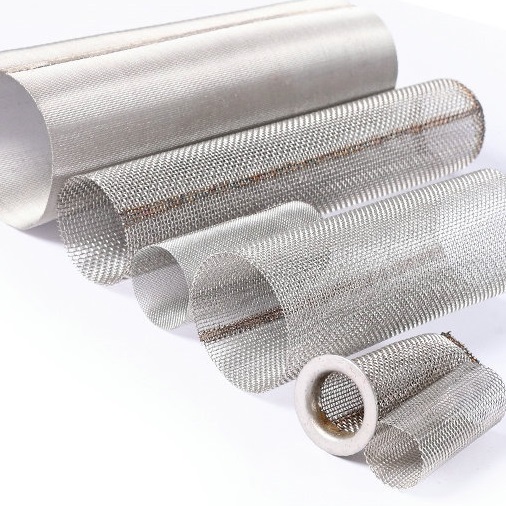

Plain Weave Stainless Steel Wire Mesh Cylinders

Stainless Wire Mesh Filter Cylinders Plain Weave

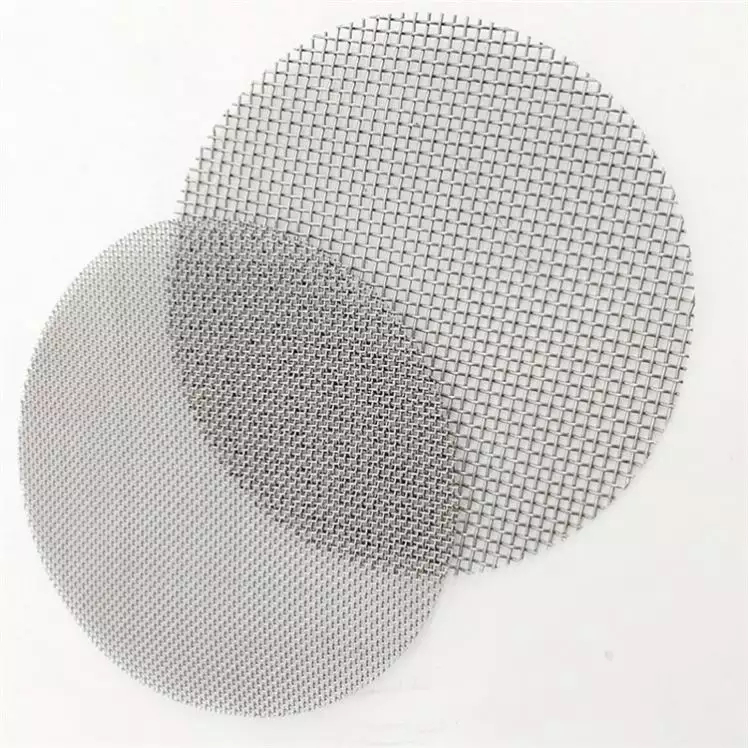

wire mesh circular disc, oval disc, and custom-made shaped disc.

Single Layer Wire Mesh Discs

Nickel Alloy C276-Hastelloy C276 wire mesh

Nickel Alloy C276-Hastelloy C276 wire mesh

Nickel Alloy 601 wire cloth-Inconel 601 wire mesh

Nickel Alloy 601-Inconel 601 wire mesh

Intermediate Crimped Stainless Wire Mesh

Intermediate Crimped Stainless Wire Mesh

Twill Weave Stainless Steel Woven Wire Mesh

Twill Weave Stainless Steel Wire Mesh

Plain Weave Stainless Steel Wire Mesh

Plain Weave Stainless Steel Wire Mesh

©COPYRIGHT METART BUILDING TEC CO., LTD | ALL RIGHTS RESERVED | PRIVACY POLICY